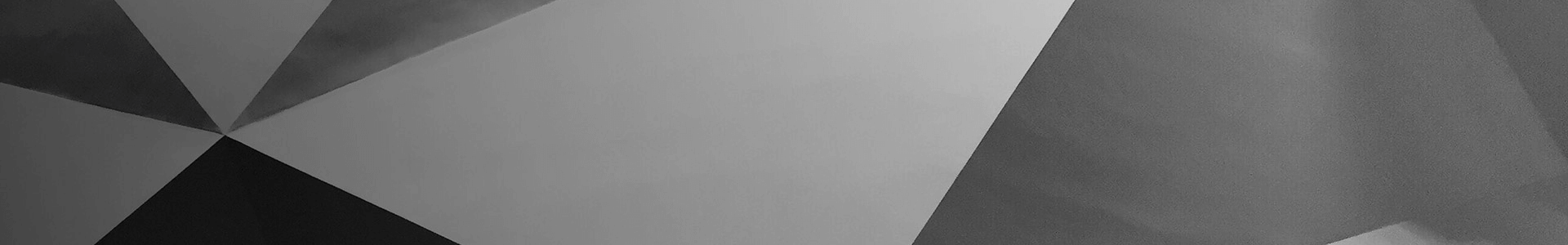

Gas Oven Stove Cooker BBQ L Type Spark Electrode Ignition Electrode Ceramic Electrode

The ignition electrode (ceramic ignition needle) bai is mainly assembled from high temperature resistant alumina ceramic;

Basic Info

| Model NO. | Ignition Electrode for Gas BBQ |

| Origin | China |

| HS Code | 8516909000 |

| Production Capacity | 50000PCS/Month |

Product Description

| Ceramics Material | 95% Alumina |

| Ceramics Length | 52.2mm or Custom |

| Ceramics Diameter | 7.5mm,6.5mm,4.5mm |

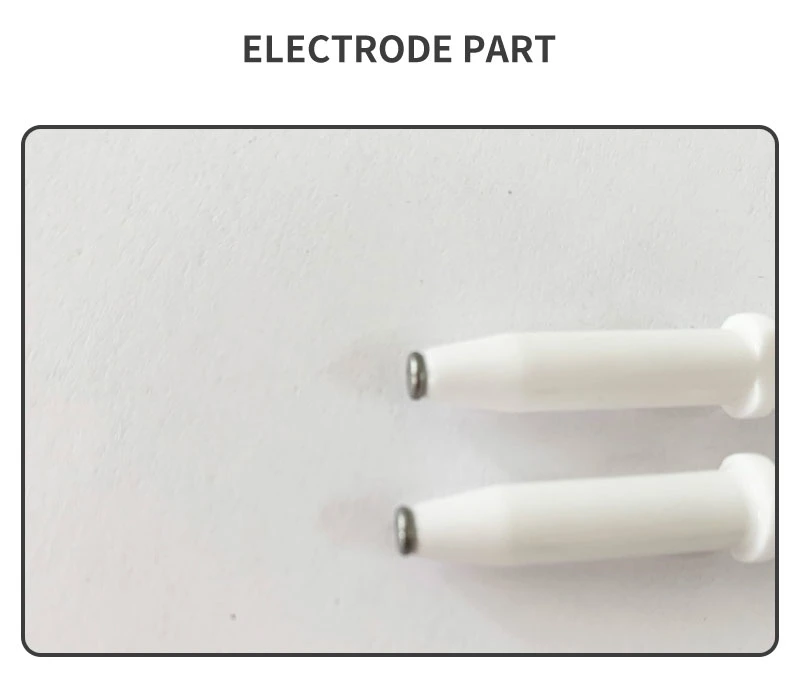

| Wire Material | Silicone Wire |

| Wire Length | 300mm or Custom |

| Color | Black |

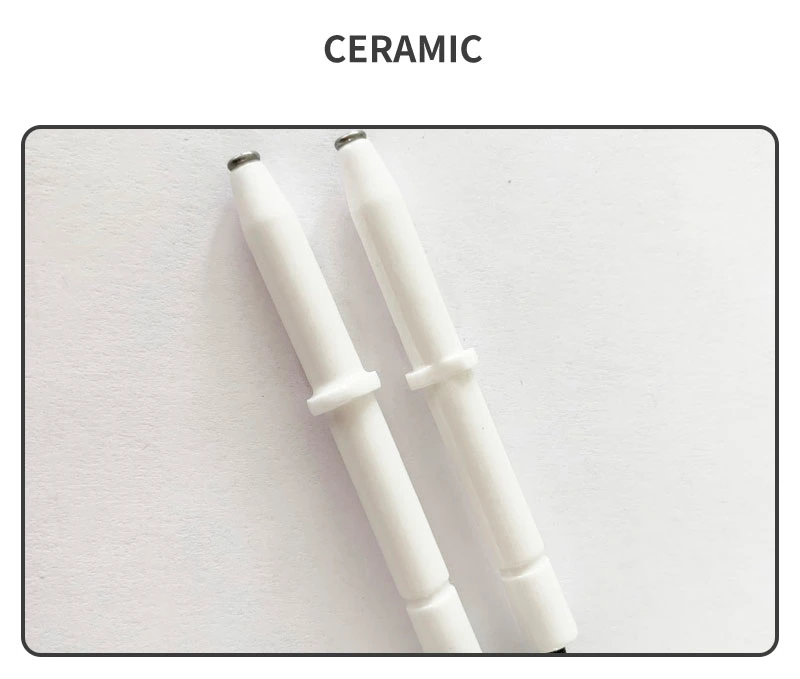

| Electrode material | Ocr25Al5 Cr20Ni80 |

| Electrode Length | 1.0mm |

| Electrode Diameter | 4.0mm |

| Used for | gas stove |

| Product name | 52.2mm ceramic length Silicone Wire gas stove ignition electrode |

The ignition electrode (ceramic ignition needle) bai is mainly assembled from high temperature resistant alumina ceramics and du resistant high temperature alloys, high temperature and high voltage wires, terminals, etc. It has the advantages of sensitive and reliable ignition, high temperature and oxidation resistance, and is widely used in liquefaction Intermittent ignition of LPG gas appliances (stove, water heater, barbecue stove, burner, gas lamp, heating stove, etc.). The high voltage resistance of the ceramic ignition electrode is greater than 18kv; the high temperature resistance of ceramic and alloy needles is less than 1400°C, the wire is used less than 300°C, and the working environment is used under RH80% at 40°C.

Alumina ceramics have good conductivity, mechanical strength and high temperature resistance. High-purity alumina ceramics are ceramic materials with an Al2O3 content of over 99.9%. Because of their sintering temperature as high as 1650-1990 ºC, the transmission wavelength is 1 ~6μm, generally made into molten glass to replace platinum crucible; use its light transmittance and alkali metal corrosion resistance as a sodium lamp; in the electronics industry, it can be used as an integrated circuit substrate and high-frequency insulating material.

The 95% alumina is made of hot pressure casting slurry and sintered at a high temperature of 1500ºC. It has the following advantages:

1. High mechanical strength and wear resistance;

2. Strong chemical resistance to acid and alkali.

3. Good electrical insulation performance at room temperature and high temperature.

4. Small mechanical strength loss under high temperature

Electrode material:Ocr25Al5 Cr20Ni80

Electrode length:1.0mm Electrode Diameter:4.0mm

Iron-chromium-aluminum resistance electric heating alloy has the characteristics of high resistivity, low temperature coefficient of resistance and high operating temperature;

Resistance electric heating alloy, this kind of alloy has stable structure, stable electrical and physical properties, good high temperature mechanical properties, good cold deformation plasticity, good weldability, and will not produce brittle fracture after long-term use. It is mostly used in the manufacture of household appliances and heating elements whose working temperature is below 1000ºC, with long service life

The inner layer is a Teflon wire, and the outer layer is a black protective wire

Teflon material has the characteristics of resistance to acid, alkali, and various organic solvents. It is almost insoluble in all solvents, and has the characteristics of high temperature resistance and extremely low friction coefficient

Yangzhou Lisheng Ceramics was established on May 31, 2010 with a registered capital of 10 million yuan. Its business scope is: electronic ceramics and ceramic accessories processing and sales. Large quantities of products are exported, mainly to North America, Japan, Europe, Taiwan, Iran and other regions.

Yangzhou Lisheng Ceramics invested 3.5 million yuan in November 2015 to rent a 2358 m2 workshop located in Shuangbao Road, Liubao Industrial Concentration Zone, Baoying County, Baoying County Liubao Industrial Zone Development, and purchased a slow mixer , Hot press forming machine, environmentally friendly gas pusher furnace, high temperature pusher electric furnace and other advanced equipment, with an annual output of 6 million electronic ceramics and ceramic accessories.

1,Are you a manufacturer or a trader?

We are a manufacturer with our own factory located in Jiangsu, China's second largest economic province;

2,What is the main product of your company?

We are a company specializing in ignition electrodes and spark plugs. Our products are widely used in gas appliances. We supply domestic well-known gas appliance companies, such as Macro, Huachuang gas appliance and other companies;

3,Whether to provide sample service?

If you have a contact person in China, we can send samples to him for free;If you are

abroad, we can provide samples for free, but you have to pay the freight yourself

4,How to contact you?

We have online shop in Alibaba, the address of the shop:yzlstc en alibaba com.

5,How long does it take from order to delivery;

It depends on the quantity of your order, usually around 10 days.

6,Can you provide customized services?

Yes, we can provide customized services, you can send us drawings, and we will make your products according to your drawings.

You may also like

Send inquiry

Send now